√High capacity by

+ All machine operation is automatic

+ Bonding TOP Side together at 2 station or TOP/BOTTOM independently

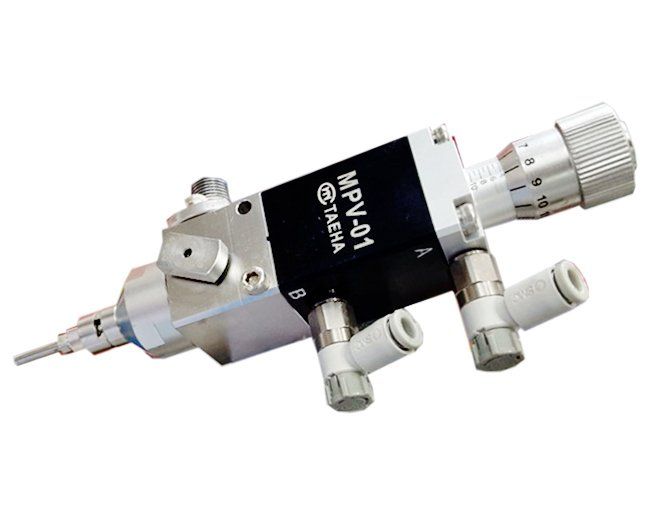

+ Use 10 Bonding Head together

+ Reduce loss time of glue in put by use Big Tank to keep glue

√Easy JOB change : Change Model by reloading Programming in HMI , Time setting is short

√Designed for Easy control, Easy maintenance and stable running

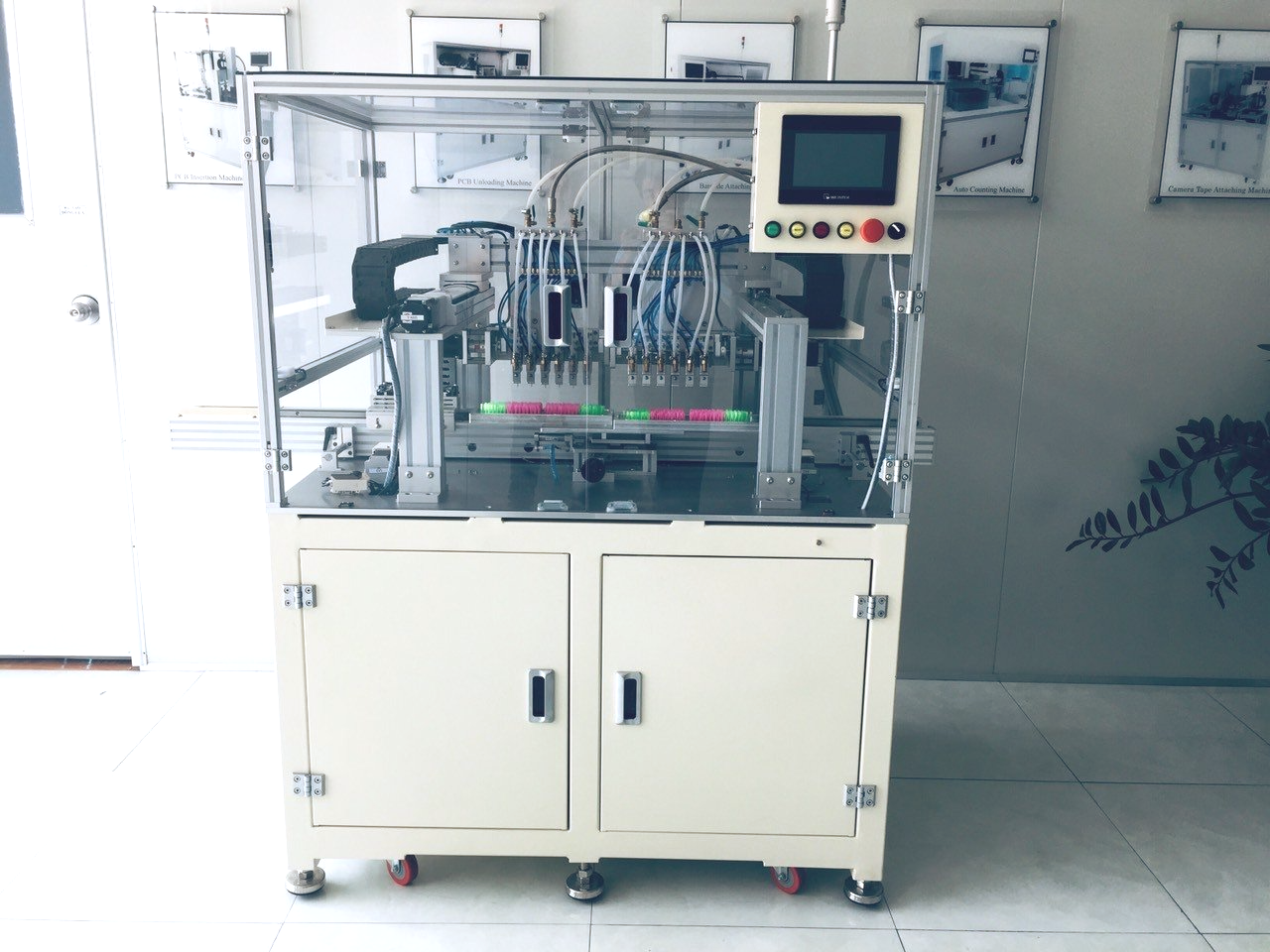

Machine Structure

Auto Transfer conveyor part

+ Auto Transfer PCBA into each station of Bonding

2) Motion X/Y/Z Part for TOP Side

+ Auto Move Bonding Head base on Position Setting

3) 2 Bonding Station and 2 rotary Part for Bonding Head

+ 1 Station have 5 Head to bonding 1 time for 5 position

And it will be set Enable bonding Position by setting based on each model

+ Bond Header can change degree by rotary part

4) Bonding Tank – 2 Set for separating TOP Side

+ One time can loading Big volume of bonding into Tank

5) Support place: Fixing PCBA when bonding

6) Control Unit

+ Easy Job change and setting machine parameter by HMI touch screen

+ Control panel was designed clearly and run stably